Understanding the New ANSI/ISEA 105 (2016) Hand and Arm Protection Cut Level Classification

In recent years, rapid technology advancement allowed manufacturers to create more sophisticated yarns that improved glove performance significantly. Cut-resistant gloves and sleeves are designed to protect hands and arms from direct contact with sharp objects made of metal, ceramic, or glass. Cut level protection is ensured by a combination of the material’s composition and thickness. The level of cut protection can be increased by using high-performance materials (Kevlar, Dyneema); composite yarns made with fiberglass, steel, or synthetic materials; by increasing material’s weight measured in ounces per square yard.

The benefit of using heavier gloves is that they provide extra protection against cuts, puncture, and abrasion, as well as provide superior durability. Lightweight glove styles now offer more dexterity and reduce hand fatigue. The advantage of coated gloves is their enhanced grip capability as well as high levels of cut protection. Today PPE users have a wide variety of options to choose from, and new standards can help facilitate the decision- making process.

What Has Changed?

The American National Standards Institute has released a new ANSI/ISEA 105-2016 Standard. The changes involve the Cut Level Rating Scale and the Method of Testing.

- A new, expanded 9-Level Classification for cut-resistance reduces gaps between cut levels 4 and 5, and expands the range of protection levels for the cut resistant gloves with the highest gram scores;

- The new ASTM F2992-15 Standard allows only a TDM-100 machine to be used for glove testing. This makes it more reproducible, and they have taken into account the dulling of the blade that occurs during testing and required a new blade is used for each cut.

The addition of new ANSI/ISEA levels will allow safety glove users to make a more informed decision about the level of protection that they need for different types of projects. Applications include: A1 - light material handling without sharp edges; A2-A3 - small parts handling with sharp edges, forestry, packaging, warehouse; A4-A5 - appliance manufacturing, pulp and paper, bottle and light glass handling, canning, dry walling, electrical, carpet installation, HVAC, metal handling, metal recycling, automotive assembly, metal fabrication; A6-A9 - sharp metal stamping, glass and window manufacturing, pulp and paper (changing slitter blades), recycling plant and sorting, food preparation and processing, meat processing, aerospace industry.

Download pdf: MCR Cut Protection Selection ANSI-CE

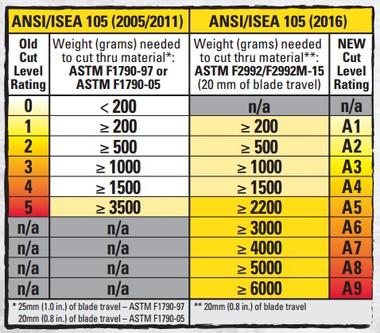

Use the table below to understand the differences between old and new cut level ratings.| OLD Cut Level Rating | Weight (grams) needed to cut through material*: ASTM F1790-97 or ASTM F1790-05 | Weight (grams) needed to cut through material**: ASTM F2992/F2992M-15 (20 mm of blade travel) | NEW Cut Level Rating |

|---|---|---|---|

| 0 | ?200 | n/a | n/a |

| 1 | ?200 | ?200 | A1 Light cut hazards |

| 2 | ?500 | ?500 | A2 Light/medium cut hazards |

| 3 | ?1000 | ?1000 | A3 Light/medium cut hazards |

| 4 | ?1500 | ?1500 | A4 Medium cut hazards |

| 5 | ?3500 | ?2200 | A5 Medium/heavy hazards |

| n/a | n/a | ?3000 | A6 High cut hazards |

| n/a | n/a | ?4000 | A7 High cut hazards |

| n/a | n/a | ?5000 | A8 High cut hazards |

| n/a | n/a | ?6000 | A9 High cut hazards |

| *25 mm (1.0 in.) of blade travel - ASTM F1790-97 20 mm (0.8 in.) of blade travel ASTM F1790-05 | **20 mm (0.8 in.) of blade travel |

If you have questions or need help finding the hand protection solution, please feel free to call us at 800-829-9580, or visit us online at www.pksafety.com.

Recent Posts

-

Promoting Safety: National Work Zone Awareness Week is April 15-19, 2024

Each year, the National Work Zone Awareness Week (NWZAW) places the spotlight on the importance o …Apr 11th 2024 -

Understanding 4 Gas Monitors: How They Work & Why They Are Important

In today’s increasingly dynamic industrial landscape, 4 gas monitors have emerged as critical com …Apr 8th 2024 -

April Showers Require Workers to Wear Hi-Vis Safety Rain Gear

While April showers bring May flowers, they also bring challenges, particularly for those working …Apr 1st 2024