Blog

Understanding the New ANSI/ISEA 105 (2016) Hand and Arm Protection Cut Level Classification

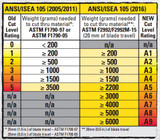

In recent years, rapid technology advancement allowed manufacturers to create more sophisticated yarns that improved glove performance significantly. Cut-resistant gloves and sleeves are designed to protect hands and arms from direct contact with sharp objects made of metal, ceramic, or glass. Cut level protection is ensured by a combination of the material’s composition and thickness. The level of cut protection can be increased by using high-performance materials (Kevlar, Dyneema); com

…

Sep 2nd 2016

How To Inspect Your SRLs To Be In Compliance With ANSI Z359

In addition to new requirements for manufacturers of

self-retracting lifelines when meeting updated ANSI Z35914 regulations, companies using the SRLs have work to do if they want to stay compliant with the American National Standards Institute's voluntary consensus standards. In creating this new standard, ANSI is trying to create a culture of SRL and fall protection inspection and certification across industries involved in at height work. It's now up to end users to inspect and maintain

…

Oct 23rd 2015

When is Hi-Vis Required? Understanding High-Visibility Requirements

Most people have heard the expression: "dress for success”. Here at PK Safety, we like to dress to stay safe. It’s critical that workers can be seen when working in road construction sites and alongside traffic to prevent “struck-by” accidents. One of the most important forms of protection for workers is high-visibility apparel.

OSHA requires high-visibility clothing but doesn't call for it outright. Under the federal worker-safety "general duty clause" companies and business owners are

…

Sep 10th 2015

Certified Anchorage vs. Non-Certified Anchorage

Fall protection needs an anchorage that is capable of holding in the event of a fall. Makes sense. But how do you know if a certain point is beefy enough to hold a full-grown man and his tools doing a 6-12 ft. free fall? Unless you've had a certified anchorage installed, chances are you won't know for certain. So try to err on the side of caution.

The old adage about anchorage points is that they need to support 5,000 lbs. We usually tell folks that if they can imagine dangling a Ford F

…

Feb 3rd 2015

OSHA Certified Airline Respirator Protection

"OSHA certified" is a bit of a misnomer. OSHA produces the standards which personal protective equipment must meet, but the organization doesn't certify equipment. The

Allegro air line respiratory systems, for example, are made to fulfill safety requirements, and are useful against a range of workplace challenges. While you need equipment that meets the OSHA requirements for your specific work place challenge, you won't find anything that is actually OSHA certified or OSHA approved.

…

Jan 27th 2015

Inspection of Fall Safety Equipment by a Competent Person

If you're working in site maintenance, oil and gas production, or other large facilities, you likely have loads of

fall protection equipment that requires periodic inspection by a competent person. OSHA sets requirements for regular inspection, and defines the type of person who can sign off on these reviews. A Competent Person in the eyes of all-mighty OSHA is simply someone who can identify the hazards of their workplace environment and who has the authorization to take immediate measure

…

Jan 19th 2015

Fall Protection Inspection Checklist

Fall protection equipment needs to be regularly inspected by a Competent Person according the specifications set forth in the ANSI Z359 protection codes if you want your Z359-rated equipment to be considered usable. Inspection is critical for all fall protection safety equipment, whether you intend to meet the highest standards in the country or not. To do this effectively, it's important to have a consistent process for the inspection. For each piece of equipment you have in your inventory,

…

Nov 17th 2014

I-Beam Anchorage for At-Height Workers

Recently a construction company contacted us to ask about using a

Miller Beam Anchor. They knew the anchor had the ability to provide anchorage for fall protection when used in a horizontal application. The 8816-14 from Miller is a typical beam anchor designed to provide an overhead attachment point on an I-beam or an H-beam. What they wanted to know was could they use the same product in on a vertical beam?

I'll keep the suspense to a minimum. Yes. Turns out Miller is perfectly happ

…

May 14th 2014

Keeping Your ANSI Z359 SRLs Compliant

ANSI Z359.1 was published in 1992 and approved a scant 15 years later. Slowly grind the wheels of progress. And ANSI Z359 is progress in terms of worker safety, even if it is going to cost more money in the short run. Greater regulation of worker safety almost inevitably means increased administrative work and expense for employers, compliance provides improved safety for workers and increased protection against litigation. Certainly these are both worthy goals, whether you're working in the

…

May 7th 2014

Inspection and Maintenance of Personal Protective Equipment

Personal protective equipment like

hard hats and harnesses aren't made to last forever. So much of this equipment has elastomeric or plastic parts that are particularly susceptible to deterioration over time. Abrasion can weaken stitching, nylon straps can be snagged and torn - even metal pieces corrode. Typically it's recommended by manufacturers that reusable PPE be replaced every 2-5 years even if it hasn't been damaged. But there are ways to extend the life of your PPE.

Safety eq

…

Apr 2nd 2014