How an SRL Works

A self-retracting lifeline can be called many different things – a yo-yo, a personal fall limiter, a seat belt, a block, or an SRL. Whatever you call it, (we like SRL) they all have similar mechanics that are part of a safety system for stopping a worker from experiencing a long fall. In this post, we will tell you how an SRL works and a little about the components that make up this life-saving device.

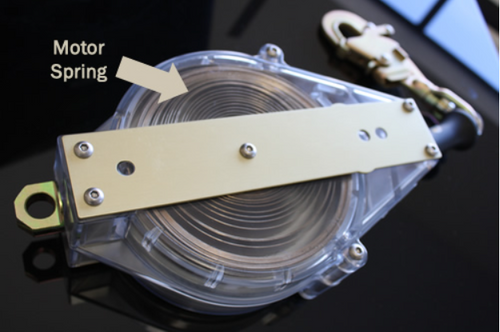

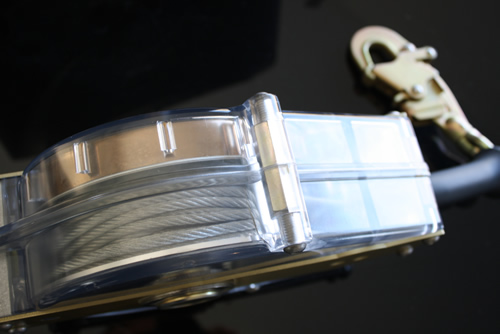

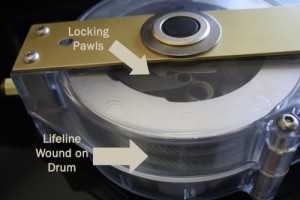

These pictures of a demonstration SRL with a clear case show you the inner-workings of these safety devices.

SRLs are a bit like retractable seat belts in your car. Once you have attached an SRL to a suitable anchorage point and to your full-body harness, the device allows you to move and work as long as you don’t move too quickly. Just like a seat belt, if you move quickly, the line stops and your movement or fall is arrested.

If you slip or fall from an edge, the SRL registers that increased speed of movement (over 4.5 ft. per second) and applies the brakes within 24 inches. That’s about 16-1/2 ft. less than you are going to need with a shock-absorbing lanyard. The SRL makes self-rescue a whole lot easier too.

An SRL has several components: the housing, the drum, a main shaft, locking pawls, a motor spring, and the lifeline itself. Let’s walk through these pieces and describe what each part does so that we can better understand just how an SRL works.

• Housing - The outer casing that holds the mechanisms of the SRL. The housing can be as small as 4-5 in. square or as large as a watermelon (but considerably heavier) depending on the length of line it holds and any additional features such as a sealed block or retrieval options. The housing is often made of cast aluminum, but can also come in steel, thermoplastic or nylon materials.

• Drum – This is the part of the SRL the lifeline winds onto when it is retracted inside of the housing. The drum can be made of aluminum, steel or high-impact plastic of nylon.

• Main Shaft – Most often a steel rod, the main shaft is positioned horizontally in the middle of the SRL and provides a rotation point for the drum and a connection for the motor spring.

• Locking Pawls/Inertial Cams – These are two types of locking mechanisms which are engaged by either centrifugal force generated around the main shaft or by inertia which pushes the braking system into action when the lifeline exits the housing at over 4.5 ft. per second.

• Motor Spring – Also called a retraction spring, this keeps tension on the lifeline when it is pulled out or let back into the housing.

• Lifeline – Made from cable (generally either galvanized or stainless steel), webbing, or synthetic rope, an SRL lifeline ranges in length from approximately 6 ft. to 195 ft. depending on the needs of the user.

With an SRL firmly attached to a suitable overhead anchor point, you are attached to the shortest possible lifeline. The motor spring keeps tension on the line and any excess is wound onto the drum. In the event of a fall, the locking pawls or internal cams apply the brakes to the lifeline before large fall forces can be generated. The lower the fall forces upon the body, the greater the chances the worker will be uninjured by the fall.

We hope this explains more about the self-retracting lifelines than you already knew. If you have additional questions about SRLs, please don’t hesitate to call or email our fall safety experts at Customer Service.

Recent Posts

-

Promoting Safety: National Work Zone Awareness Week is April 15-19, 2024

Each year, the National Work Zone Awareness Week (NWZAW) places the spotlight on the importance o …Apr 11th 2024 -

Understanding 4 Gas Monitors: How They Work & Why They Are Important

In today’s increasingly dynamic industrial landscape, 4 gas monitors have emerged as critical com …Apr 8th 2024 -

April Showers Require Workers to Wear Hi-Vis Safety Rain Gear

While April showers bring May flowers, they also bring challenges, particularly for those working …Apr 1st 2024